| Sign In | Join Free | My wpc-board.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My wpc-board.com |

|

Brand Name : MG

Model Number : MGDM-3.7

Certification : CE, ISO9001:2008

Place of Origin : China

MOQ : 1 set

Payment Terms : T/T, L/C, D/A, D/P, MoneyGram, Western Union

Supply Ability : 20 sets per month

Delivery Time : 20-25 working days

Packaging Details : Stand seaworthy packaging

Product name : Tile adhesive mortar Full automatic dry mix plant

Color : Customized

Workers required : 3-4 people

Voltage : 220V-440V, 50/60Hz or customized

Warranty : 12 months

Advantage : Factory directly More than 20 year experiences

After-sales services : Engineer available to service machinery overseas

Machine occupy area : 100-200m2

Dosing and Packaging : Automatic dosing and automatic packing

Control cabinet : PLC control cabinet

High efficiency tile adhesive mortar Full automatic Dry Mix Plant with PLC control cabinet

Description of MG automatic dry mix plant:

Full Automatic Dry Mix Plant, capacity 10-30t/h, is based on the latest Germany technology, this production line adopts automatic control system, its capacity at 30-100 thousand tons per year depended on different configuration.

Dry mix mortar plant is generally used to produce various ordinary and specific mortars, which includes plastering mortar, masonry mortar, waterproof mortar, tile adhesive mortar, wear-resisting floor mortar, thermal insulation mortars and etc.

Dry mortar mix plant basically consists of wet sand feeding system, drying system, hoist lifting system, raw material storage system, weighting system, mixing system, finished product storage bin, packing system, dust collector and control system.

Technical parameters of MG automatic dry mix mortar plant:

| Automatic Dry Mix Plant | |||

| Capacity | 10-30T/H(depending on machine configuration) | ||

| Machine occupy area | 100-200m2 | ||

| Assumed bulk material density | 1.4kg/m3 | ||

| Number of circles/hour | 15-20(depending on applied formula) | ||

| workshop Area | 1000-1500m2 | ||

| Packing type | Bag packing or bulk loading as requirement | ||

Configuration of MG automatic dry mix plant:

1) Sand drying system

2) Coarse material storage system

3) Automatic weighing system

4) Conveying system

5) Mixing system

6) Air compressor system

7) Packaging system

8) Dedusting system

Application of MG automatic dry mix plant:

Dry mortar plants suitable for practically all demands, such as:

1) proprietary adhesive and mortars for aerated concrete;

2) glue mortar for ceramic wall tiles;

3) masonry mortar; skim coat;

4) inside plaster; outside stucco;

5) concrete;

6) floor screed Benefits for the builder;

7) Usage for many kinds of construction material, such as autoclaved aerated concrete (AAC), rock,

calcium silicate bricks, masonry blocks, tiles, joints, etc;

MG dry mix plant in customer factory:

MG dry mix plant loading to foreign customers:

Our services:

1)Unpon got your inquiry, We will reply to you in 24 hours.

2) Assist clients to prepare for the first construction scheme and supply foundation drawing.

3) Oversea installation and provide technical exchange, train client to operate the machine.

4) Supply spare and accessory parts at favorable price for long-term.

5) Spare part are original, authentic, good quality, can be avaible from stock, and sent to client, immediately by

DHL, EMS, Fedex, and by air, gurantee client to receive it in shortest time. Strict site quality inspection system:

Installation captain inpection: Evaluate the installation level of dry mix mortar production line, Spot QA engineer inspection: Inspect the whole in installation process and key components.

Service engineer inspection: Inspect the debugging and running condition of whole production line.

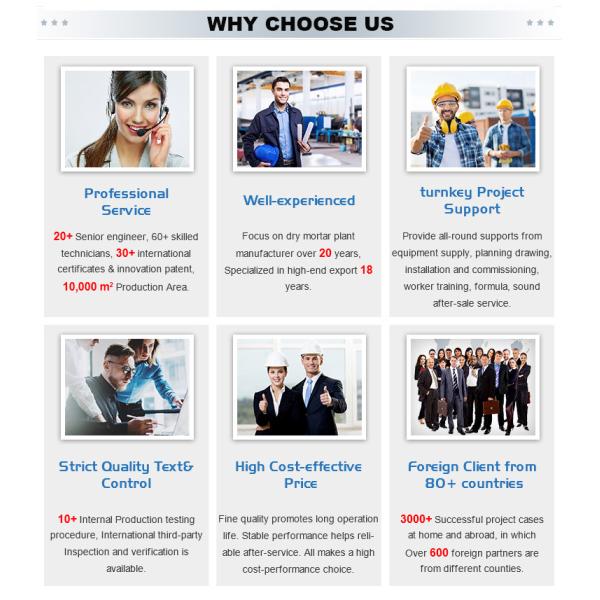

We are professional manufacturer of dry mortar machines, our company dedicated in this field for more than 20 years, we alreays provide our customer turnkey project of dry mortar plant from working site planning to machine installation and commissioning, formula, opeation training, technical support etc. Escort for your sucess!

|

|

High Efficiency Tile Adhesive Motor Full Automatic Dry Mix Plant Customized Color Images |